It’s absolutely critical for this kind of low batch production that we do.” All components that require precision installation are cut on an Andi CNC Router, from the Anderson Group, and programmed by Cabinet Vision’s Screen-To-Machine module. The fast turnaround that Cabinet Vision gives us is extremely important. “That’s extremely useful to us and means that with better job control we can better manage our stock levels, reducing high-value stock being stored here instead of it being installed and invoiced.

#CABINET VISION 12 TUTORIAL SOFTWARE#

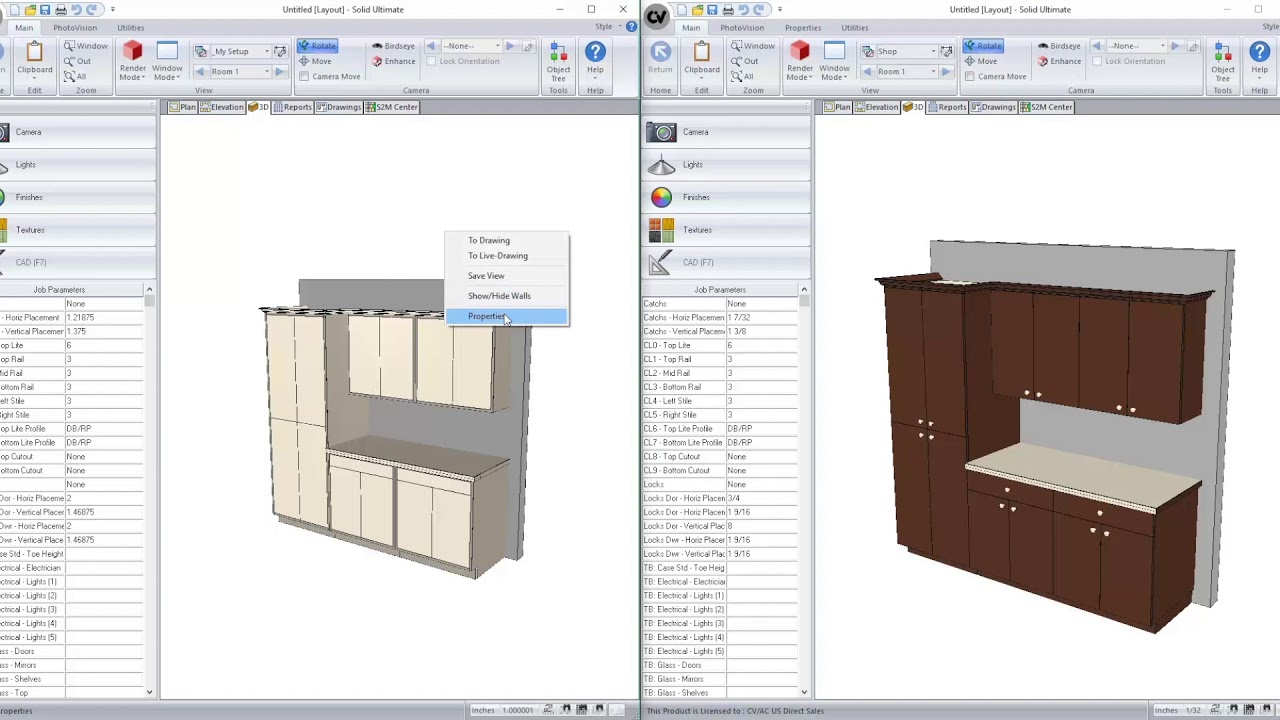

The ability to do everything in one software package has been benefiting the business ever since. This starts with the sales drawing and carries on right through to the finished product coming off the production line.” We were aware that we couldn't do this without some kind of CAD package, and Cabinet Vision offered an ideal on-stop system that we could use for every step of the process. Once they began to offer a more complex product range they knew they would require a CAD software package, “We began using Cabinet Vision when we purchased our first CNC Router. Combined with a fast turnaround time, in house manufacturing and the element of product fragility, he says this has been a winning formula against overseas competition.

As a result, they began to specialise in bespoke wardrobe products involving a range of materials – glass, mirror, wood and metal. This huge range of customer profiles requires us to be very responsive to changing design requirements whether it be one bedroom with an out of vertical wall or an entire site with 20 different designs and multiple options.”ĭraks originally focused on manufacturing plantation shutters, however as the market size grew, they found the product vulnerable to competition from cheap imports. We also work for a number of smaller companies building between 20 and 100 homes a year. Chris Ayres says: “We work with a number of large property developers, including the Berkley Group, Taylor Wimpey and Spitfire Bespoke Homes. Sited on a former American Air Force base at Upper Heyford in Oxfordshire, the premises comprise a 15,000 square foot manufacturing facility, and an additional storage unit. Working in the industry for over 20 years, they have built up a reputation for quality through their customer-focused approach, combined with technical and design expertise. Using Cabinet Vision as their sole CAD/CAM solution, home interior manufacturer Draks Interior Door Systems Ltd have been able to take jobs from design to finish in one single system, allowing a quick and smooth internal process.ĭraks Technical Director Chris Ayres says: “Being able to do everything with just one software package, means that everything, including the transition from CAD to CAM is done seamlessly, which is extremely useful.”Ĭurrently operating with 29 employees, Draks Interior Door Systems Ltd produce customised home solutions, mainly focusing on design-led hinged and sliding wardrobe doors, wardrobe interiors, room dividers, walk-in wardrobes and bathroom cabinets to the new build sector.

0 kommentar(er)

0 kommentar(er)